How should I inspect my mobile concrete batching plant before starting it?

28th Aug, 2022

Mobile concrete batching plants are high-valued items that need to be inspected, cleaned and maintained correctly to ensure a long lifespan and minimal downtime for repairs and maintenance.

Inspecting your mobile concrete batching plant before starting it is imperative and will ensure that you catch any potential issues if they arise.

Mobile concrete batching plant inspection guide:

- Inspect the electrical connections of the control panel to check if there are any open wires, loose connections, etc.

- Check that the indicator, load cells and the large scoreboard is in working condition.

- Check all electrical cables for any damages.

- Check the water pump, meter, pipes and fittings for any leaks.

- Check the conveyor belt's condition for wear and tear.

- Ensure the conveyor belt is aligned and that it runs straight to prevent it from drifting.

- Remove any debris under the conveyor belt at the tail pulley to prevent the belt from damaging.

- Ensure that the bearings are cleaned and greased to keep them in optimal working condition.

- Check the aggregate hopper door stoppers, to prevent the doors from opening too wide and causing overloading of the conveyor belt. Also, check that the door handle is in good working condition and that the bushes have been cleaned and greased.

- Inspect the area around the plant and ensure that the area is clear to prevent employees tripping and injuring themselves.

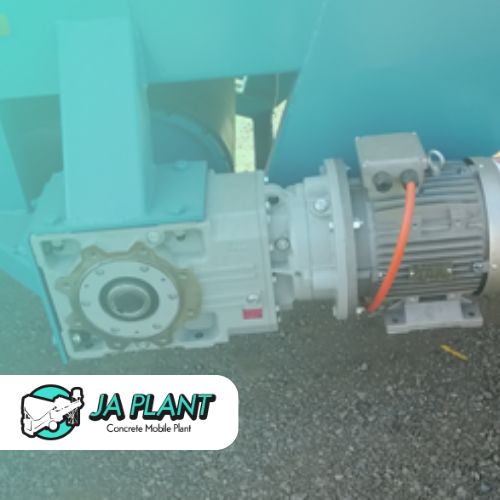

- Check the gearbox and motor for any oil leaks and damages. (Check the fan cover, seal on gearbox, etc.)

- Ensure the safety guards are secured.

- Inspect the loading ramp.

- Inspect the Head Shute for any access concrete and clean the area if needed.

Noticing worn-out or damaged parts and replacing them quickly can help prevent costly repairs down the line. In addition, if your batching plant is out of action due to a lack of maintenance, you could lose unnecessary operational hours and lose money.

Need help with servicing or finding parts for your mobile batching plant? Contact JA Plant today!